The Decision Model for Gate Allocation. Silvie Spreeuwenberg, Librt

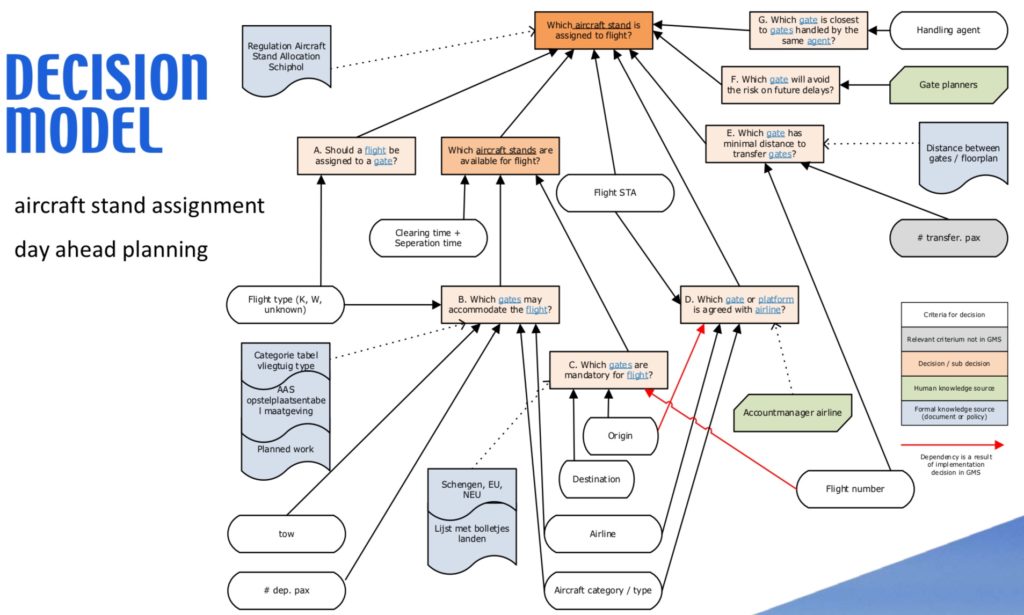

Day 3 of DecisionCAMP 2019 started with three use cases from industry. First, Silvie Spreeuwenberg presented on decision models for allocating airport gates, specifically at Schiphol airport in Amsterdam. Although gate plans are made a day in advance based on flight schedules, they change constantly due to early arrivals, late departures and other unexpected disruptions to the schedule. Any given day, there are 50-100 gate changes one hour before an aircraft arrival; although this was seen as a disruption, this could also be considered an opportunity for optimization.

There were a lot of rules used for the planning and reassignment that had more to do with preferences than actual optimization; they really wanted to drive towards the objective of optimizing asset usage and therefore airport capacity. There are a lot of factors involved, such as having sufficient gate area capacity to handle the number of passengers for a flight, or having buses available to offload flights that can’t be assigned a gate. They have created a policy for aircraft stand allocation which includes some identifiable decision tables, although these are just at the strategy documentation phase.

Definitely a complex problem that has applicability at every major airport around the world.

A hybrid implementation of multi-channel, multi-modal, high volume financial risk monitoring. Martijn Tromm and Marten Schokking, Oracle

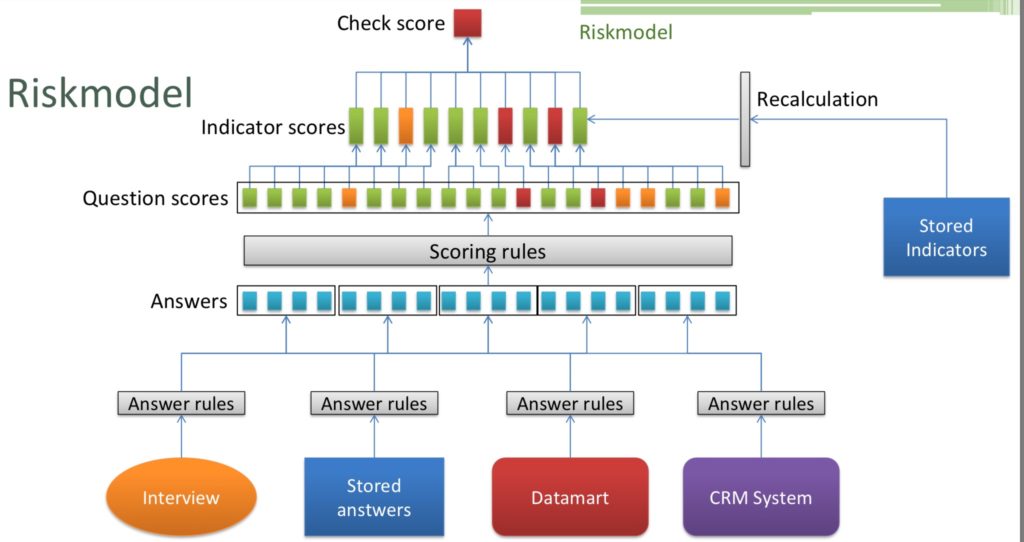

Marten Schokking and Martijn Tromm presented a use case from Rabobank using decision management and machine learning for customer risk assessment in terms of KYC (know your client) and AML (anti-money laundering). This is used during client onboarding, but also during periodic reviews as well as reviews triggered by specific events. There are scoring rules that use data input from a variety of sources, including client information from a CRM, interview responses and policies.

There are government regulations requiring that this be done for all clients at certain times. A triggering event, such as a change in the customer’s circumstances, will cause a customer interview and other data analysis to recalculate the risk; this may result in a more detailed manual review of the risk. At this point, there is still a lot of employee work which is creating a challenge in completing the customer risk assessments within the regulatory deadlines; they are looking at how to automate the basic assessment using machine learning in order to reduce the manual work required.

The risk model has been built using Oracle Policy Automation rules engine integrated with the Siebel CRM. They are reusing rules across channels where possible, and the use of natural language in the rules definition helps with traceability to the policies. They are continuing to innovate with rules, such as having context-driven rules based on user behavior on specific channels, and having a fast two-day turnaround for rule changes related to certain types of policy changes. The ability to predict the impact of policy changes based on actual data allows for operational planning to accommodate those changes.

The Role of DMN and BPMN in the Design of Composite Materials. Dario Campagna, ESTECO

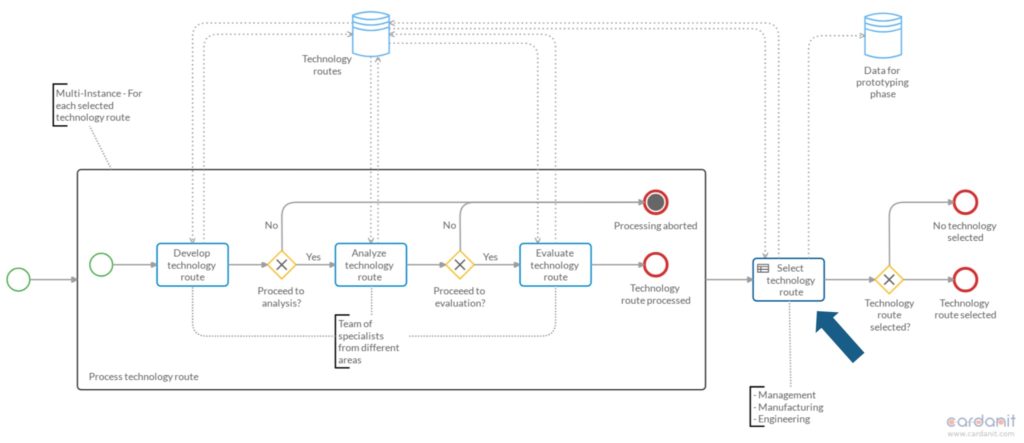

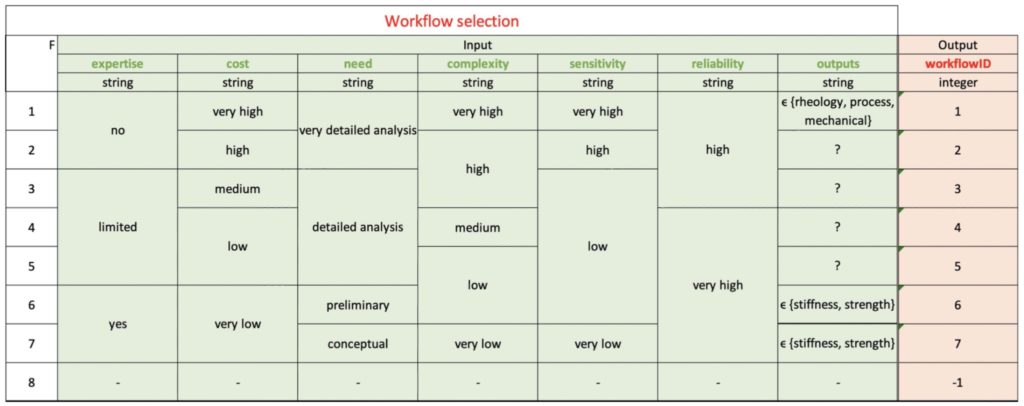

Dario Campagna presented on how the COMPOSELECTOR project is integrating material modeling and business process management in a decision support system for composite material design; this type of design can have complex requirements, business decisions and simulation workflows. Using application cases from Dow, Airbus and Goodyear, they modeled the business flow using BPMN and DMN. ESTECO, which creates software tools for engineering design, is a contributor to the COMPOSELECTOR project.

While BPMN is used to model the flow at the business level, DMN decision tables are used to make decisions on the class of materials and manufacturing process, then on the simulation workflows to use based on business and engineering KPIs. DMN provides the link from the business layer to the engineering layer, then to the simulation layer. Using DMN provides a higher level of consistency in decision-making, which leads to better design and lower costs.

We saw a brief video of a demo of the system in use: a business-level manager selects high-level parameters and KPIs for the proposed design; this selects one or more simulation models for the material design, which is then confirmed or decided by an engineer; the results of the simulation are passed back to the manager for final decision-making. This has the effect of integrating the business and technical sides of the design process, and include modeling and simulation results in the business-level (human) decisions in a standardized way.