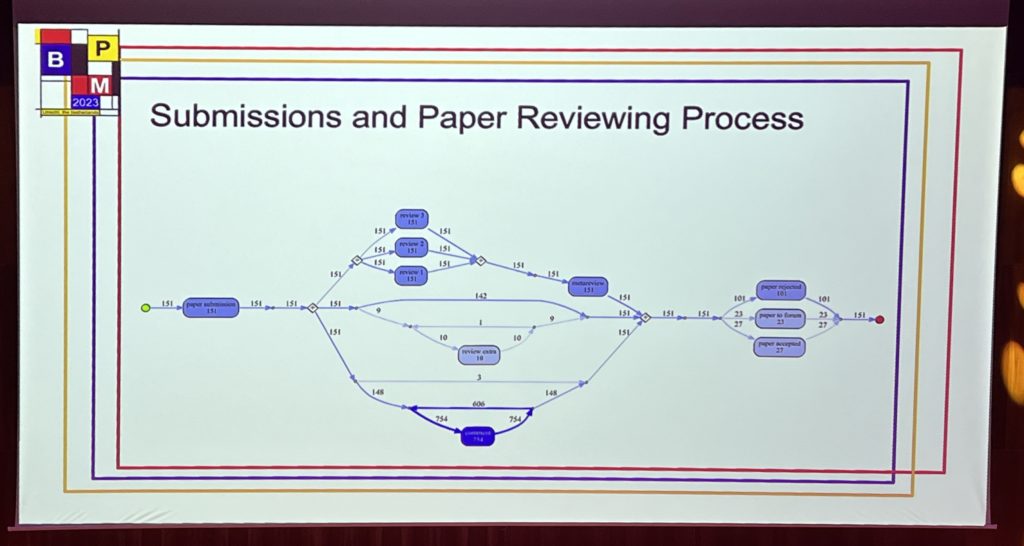

Following yesterday’s workshops, the main conference kicked off today with an introduction from the organizers, which included a diagram of the paper acceptance process that was mined from the actual activities in the paper submission and review platform — did anyone else find this funny? We’ve also moved from the beautiful, historic and non-air-conditioned university buildings to the artistic and somewhat cooler TivoliVredenburg concert hall.

We then had the opening keynote by Marc Kaptein, Medical Director at Pfizer. He was involved in vaccine development, among other activities at Pfizer, and provided some insights into how process optimization allowed them to manufacture billions of vaccine doses in record time. He is a medical doctor but also a Six Sigma black belt, which means he has a strong sense of how good processes matter.

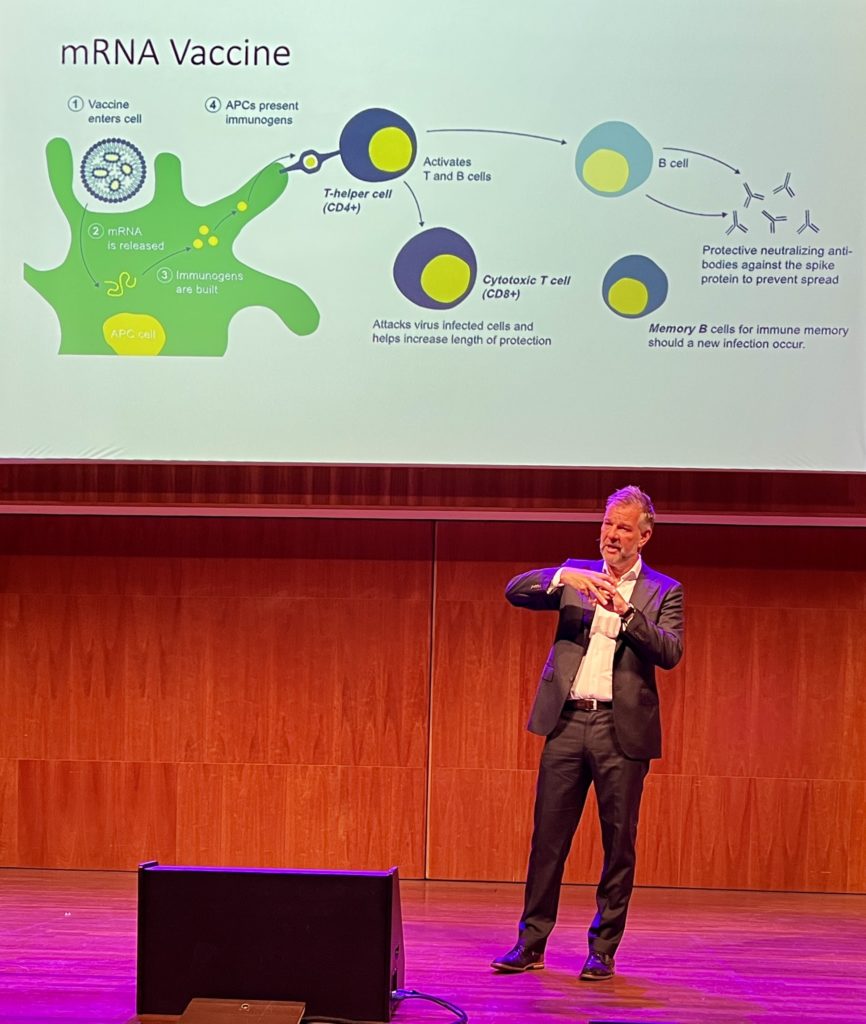

He walked us through the COVID crisis from the initial thoughts that it could be isolated geographically (spoiler: it couldn’t), to the research that led to the development of mRNA type vaccines. He mentioned a number of the international researchers in different organizations who contributed along the way, and gave a great explanation of how mRNA vaccines work. He credited the CEO of Pfizer with going all in with whatever funding was required to develop a vaccine — “If we don’t do it, who will?” — and for refusing US government funding since the concomitant oversight/interference would have slowed them down. (Moderna took the funding and ended up releasing later than Pfizer)

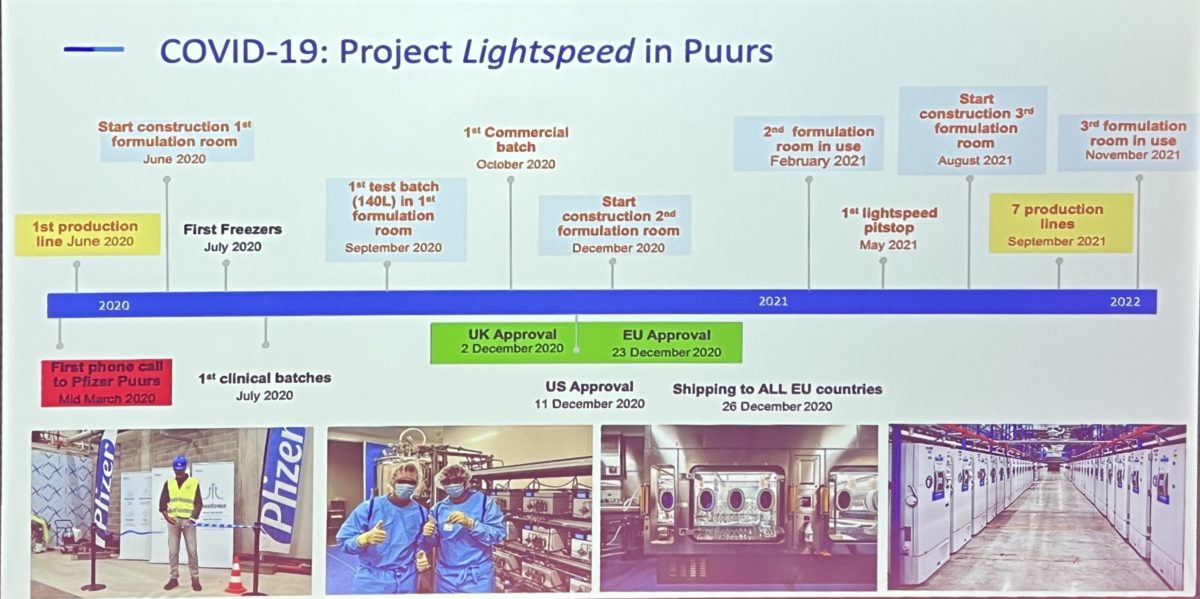

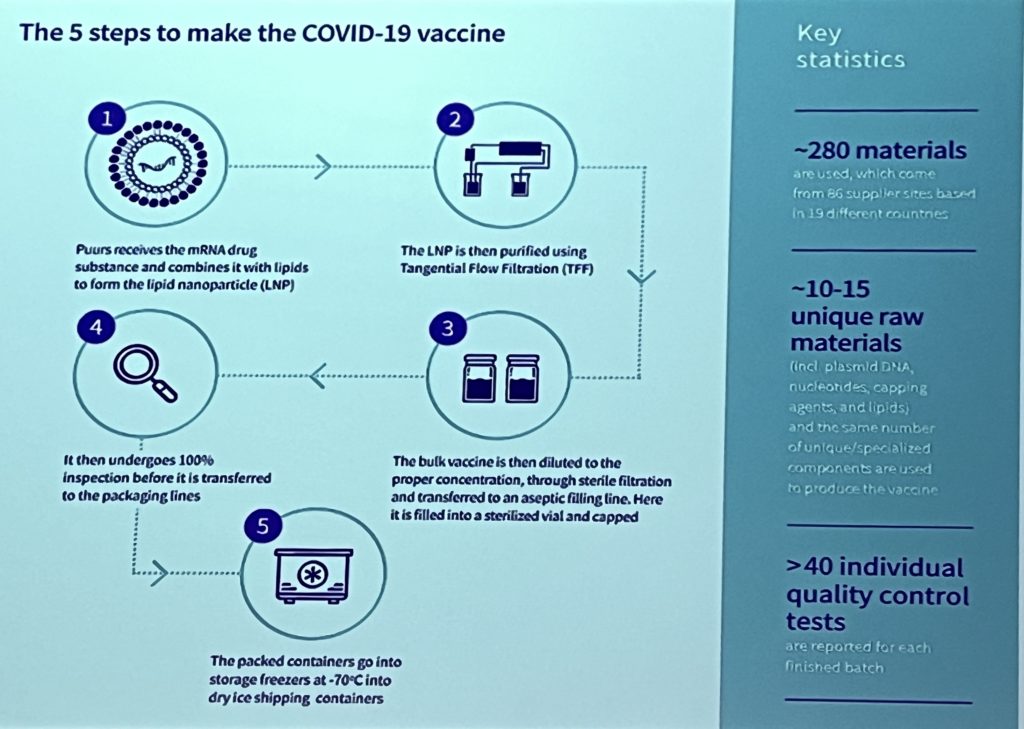

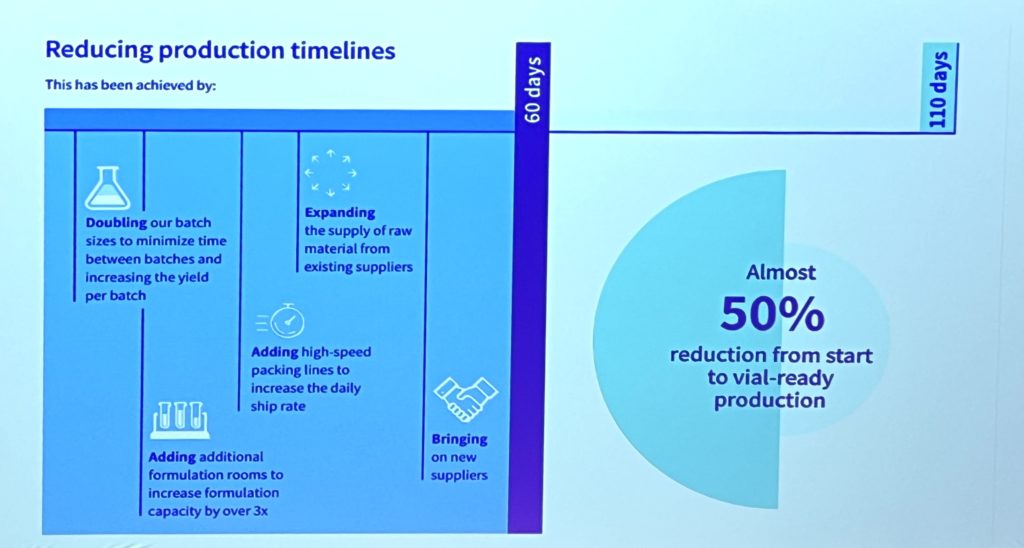

Once they had done their initial trials and proved the efficacy of the vaccine, they were then faced with the manufacturing process problem: how to get from one to one billion in the shortest period of time? Even before they had trialed the vaccine, they were readying the production facilities to ramp up for this volume. They also invested in ensuring the supply of the lipids and mRNA, including ways of decreasing the time required to create mRNA. They also optimized more of the mechanical aspects of production, such as speeding up the vial filling process, moving to 100% automated inspection, and improving the capping and labeling processes. They improved their production maintenance cycle from a month to five days. They expanded their freezer farm facilities, and ended up building their own dry ice manufacturing facility since their suppliers couldn’t keep up with their demands.

All of these improvements led to almost 50% reduction in production cycle time from 110 days down to 60 days, which allowed them to produce an amazing 1.2 billion doses in 2021 and 2 billion in 2022. Kaptein pointed out that this won’t be the last pandemic, and these improvements to the process and production speed will serve everyone in the future.

Disclaimer: I’ve had five vaccinations including AstraZeneca, Pfizer and Moderna, so I’m completely non-partisan about big pharma. 🙂