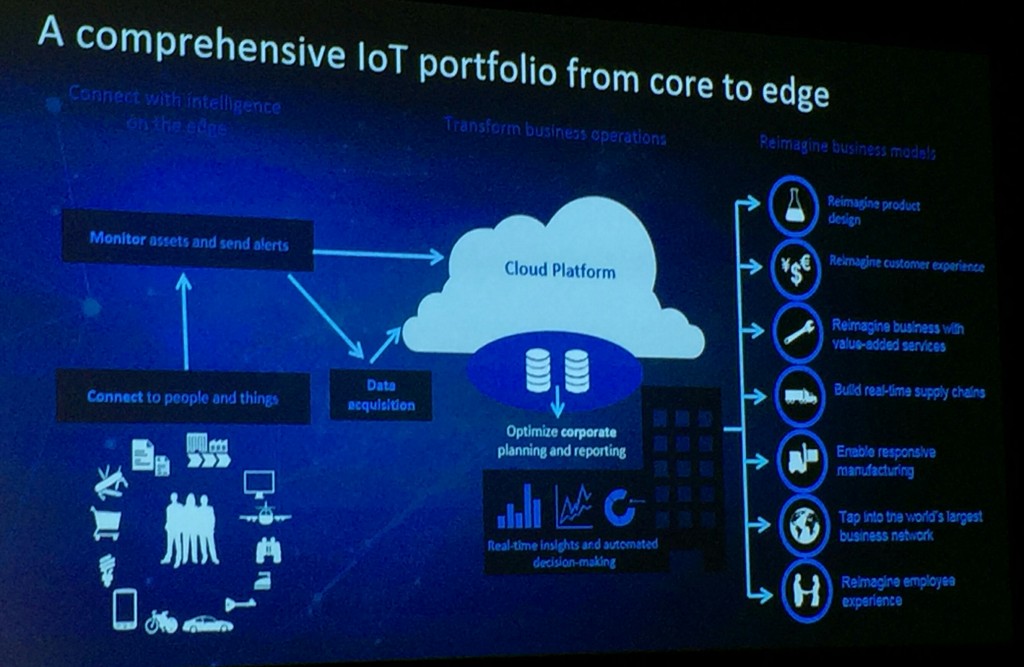

Steve Lucas, president of platform solutions at SAP, led a panel on the internet of things at SAPPHIRENOW 2015. He kicked off with some of their new IoT announcements: SAP HANA Cloud Platform (HCP) for IoT with free access to SAP SQL Anywhere embeddable database for edge intelligence; a partner ecosystem that includes Siemens and Intel; and customer success stories from Tennant and Tangoe. Their somewhat complex marketecture diagram shows a fairly comprehensive IoT portfolio that includes connecting to people and things at the edges of your value chain, and integrating the events that they generate to optimize your core corporate planning and reporting, providing real-time insights and automated decisioning. The cloud platform is key to enabling this, since it provides the fabric that weaves all of the data, actions, rules and decisions into a single connected enterprise.

He was joined on stage by Austin Swope, who demonstrated remote equipment monitoring using a tiny but operational truck on the stage, complete with onboard sensors that pushed events and data to the cloud for remote monitoring and problem detection. We saw some of the real-time analytics (when the wifi cooperated) on-screen while the truck ran around the stage, and some of the other types of dashboards and analytics that would be used for broader equipment management programs. Since the equipment is now fully instrumented, analytics can be used to visualize and optimize operations: reducing costs, improving maintenance cycles, and increasing equipment load factors through a better understanding of what each piece of equipment is doing at any given time.

Next, Lucas was joined by Gary Hayes, CIO of CenterPoint Energy; Paul Wellman, CIO of Tennant; and Peter Weckesser, CEO Customer Service, Digital Factory at Siemens. Hayes talked about how CenterPoint is using smart meters, grid storage, digital distribution networks and other IoT-enabled technologies to drastically reduce costs and improve service, while maintaining safety and security standards. They’re starting to use predictive analytics on HANA to model and predict underground cable failures, and several other innovations in intelligent energy management. Wellman discussed how Tennant, which has fleets of large-scale cleaning machines such as you would see in conference centers and airports, has added telemetry to provide machine monitoring and predictive maintenance, and expose this information to customers so that they can understand and reduce costs themselves through fleet management and usage. Last up, Weckesser talked about how Siemens devices (of which there are millions out there in a variety of industrial applications) generate events that can be analyzed to optimize industrial plants and machines as well as energy and resources As an SAP partner, Siemens is offering an open cloud platform for industry customers based on HANA; customers can easily connect their existing Siemens devices to the Siemens Cloud for Industry apps via public cloud, private cloud or on-premise infrastructure. This allows them to do analysis for predictive maintenance on individual machines, as well as aggregate fleet operations optimization, through apps provided by Siemens, SAP, SAP partners or the customers themselves.

I was disappointed not to see the SAP Operational Process Intelligence offering involved in this discussion: it seems a natural fit since it can be used to monitor events and control processes from a variety of underlying systems and sources, including event data in HANA. However, good to see that SAP is providing some real-world examples of how they are supporting their customers’ and partners’ IoT efforts through the HANA Cloud Platform.